Call: 01455 251151

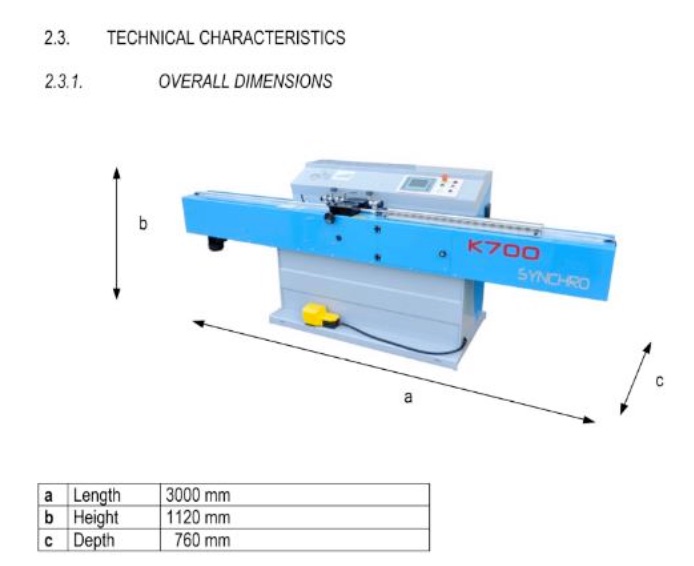

The ATLANTIC K700 Synchro Butyl Extruder

A PIB Butyl extruder is specialised equipment used in the manufacturing of insulated glass units (IGUs) for applying Polyisobutylene (PIB) sealants. These sealants, commonly known as PIB Butyl, are applied to spacer bars or directly onto glass surfaces to create a durable and effective seal between the glass panes in the IGU. The extruder ensures precise and consistent application of the PIB Butyl sealant, contributing to the overall quality and performance of the finished IGUs.

Features

- Extrudes on to Spacer Bar 4mm - 30mm.

- 10 – 38 mtr/min adjustable extrusion speed.

- Omron PLC , Touchscreen Controls and fault finding.

- Digital display for nozzle gap setting.

- Unique bar centralising clamps .

- Footswitch and clamp for coating shaped spacer bar.

- Silicon belt for cleanliness.

- Application to aluminium, stainless and warm edge bar.

- 7 day warm up timer.

Technical

- Max operational Hydraulic pressure 150 Bar.

- Sealant chamber for standard 7KG format slugs.

- Service requirements: 32Amp 3 phase and compressed air.

Options

- Automatic width adjustment for varying spacer cavity.

- Automatic belt height adjustment for varying spacer profiles

- Centralised bar clamping for precision butyl application

Models

- K700 Synchro