Call: 01455 251151

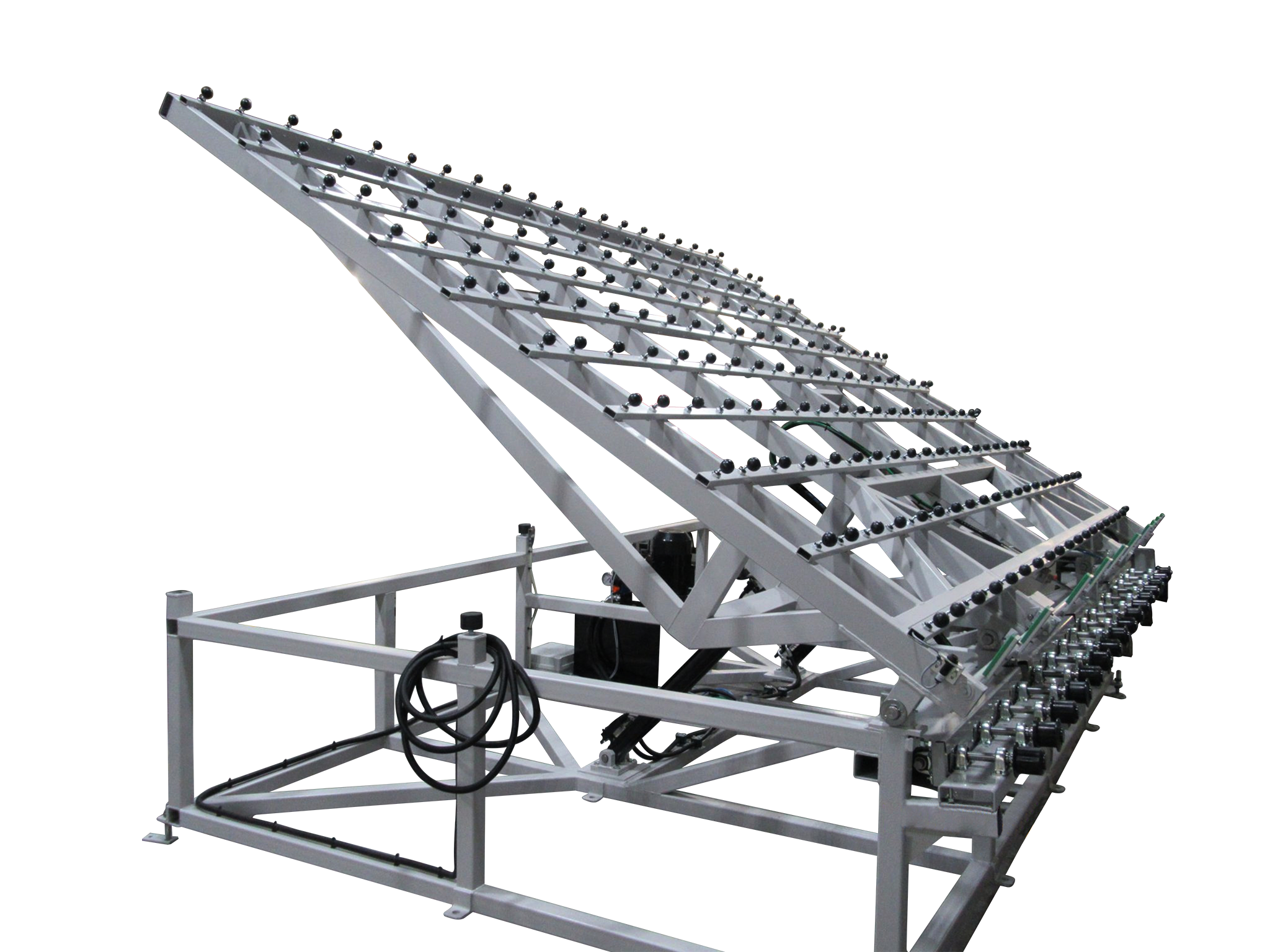

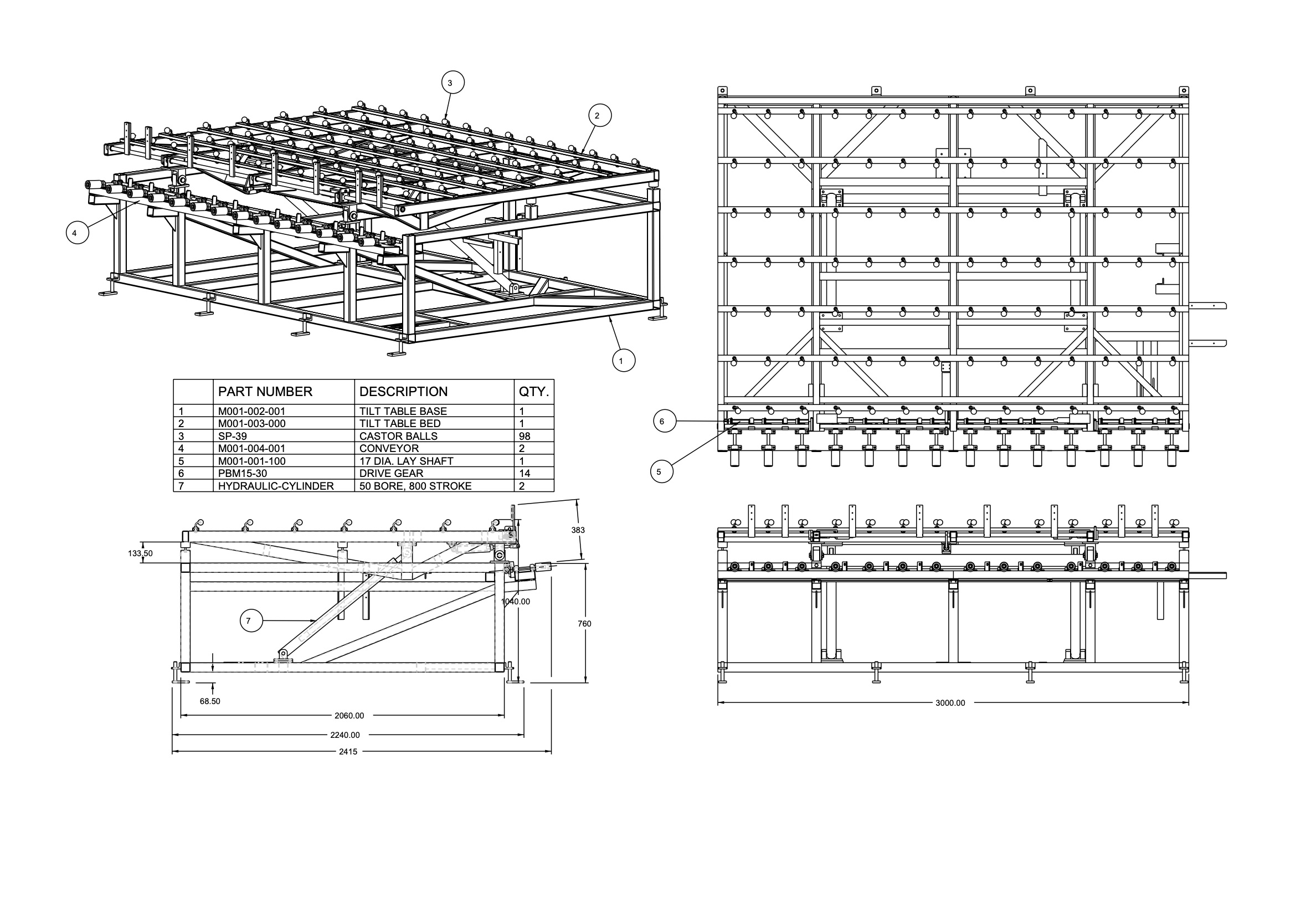

Hydraulic Tilting Table

This PLC-controlled machine efficiently presses pre-assembled units with Poly-Iso-Butylene (PIB) applied to the spacer bar, creating a primary sealed unit ready for gas filling and final sealing. It's versatile, accommodating structural foam spacer bars like 'Superspacer'. The press seamlessly integrates into a semi-automatic line or operates as a standalone unit at the end of an existing glass washer unit.

Features

- Safe and solid operation using hydraulic rams

- Sealing suction cups integrated into the table

- Can be used with any Atlantic Washer and Glass Assembly Line

- Multi directional rubber rollers

- Glass height horizontal 1000mm

- Glass height vertical 760mm

- Standard table to suit glass 3mtr x 2mtr, 750kg loading

- 16 Amp 3phase and compressed air required.

Options

- Sizes up to 5 mtr x 3mtr

- Choice of sealing cup positions to suit factory layout

- Reconditioned units sometimes available.