Call: 01455 251151

Straight Line Edgers (SLE) & Bevellers – Glass Polishers

Straight Line Edgers (SLE) and Bevellers, also known as Glass Polishers, are vital equipment in glass processing facilities for shaping, grinding, and polishing glass edges to achieve desired finishes and dimensions.

Straight Line Edgers & Bevellers Defined

Straight Line Edgers (SLE) and Bevellers, often referred to as Glass Polishers, are essential machines used in glass processing facilities for shaping and polishing glass edges.

Straight Line Edgers (SLE) are machines designed to grind and polish the edges of flat glass sheets to achieve a smooth, uniform finish. They feature multiple grinding wheels arranged in a straight line configuration, which allows for efficient processing of glass edges in a continuous motion. SLE machines are commonly used to produce glass panels with straight and polished edges, suitable for various applications such as windows, doors, and furniture.

Bevellers, on the other hand, are machines specifically designed to create beveled edges on glass. Beveled edges are characterised by angled edges that add decorative appeal and depth to glass panels. Bevellers utilise grinding and polishing wheels to shape the edges of the glass at the desired angle, resulting in a beveled edge with a smooth and polished finish. These machines are commonly used in the production of decorative glass items, mirrors, and architectural applications.

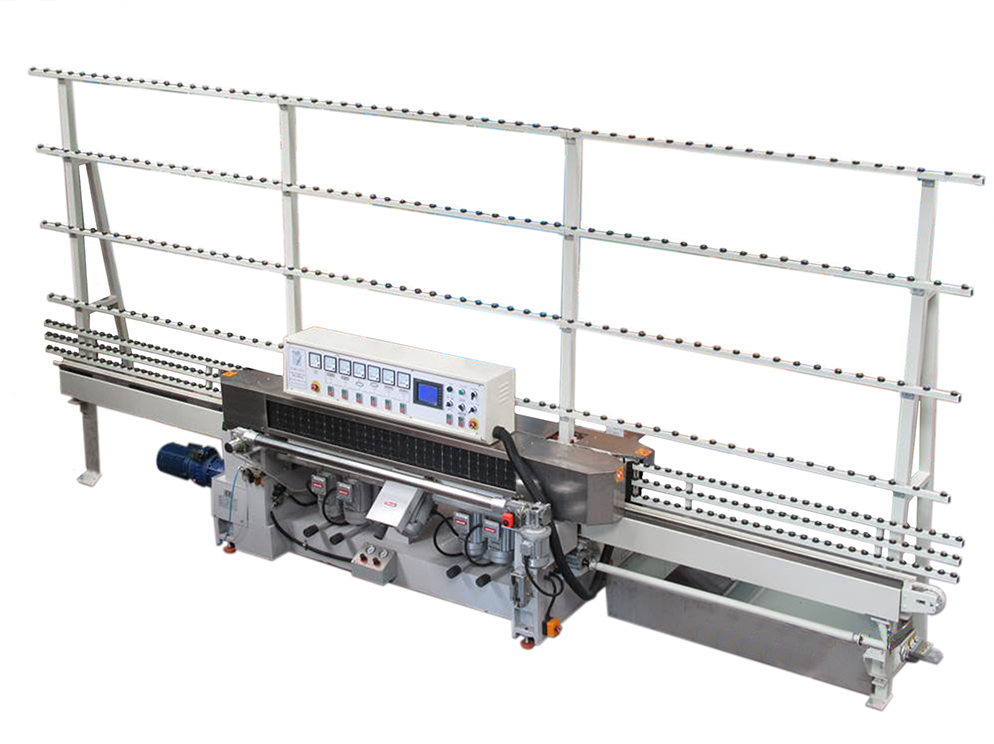

4 Spindle SLE

The Atlantic ASL4/5 is a compact and user-friendly machine specifically designed for grinding and polishing the bottom edge of glass, with front and rear arris grinding capabilities. It delivers a uniform finish across glass thicknesses ranging from 3mm to 25mm.

6 Spindle SLE

The ASL6.325A is a 6-spindle edger machine designed to provide bottom edge grinding and/or polishing, depending on the desired finish quality.

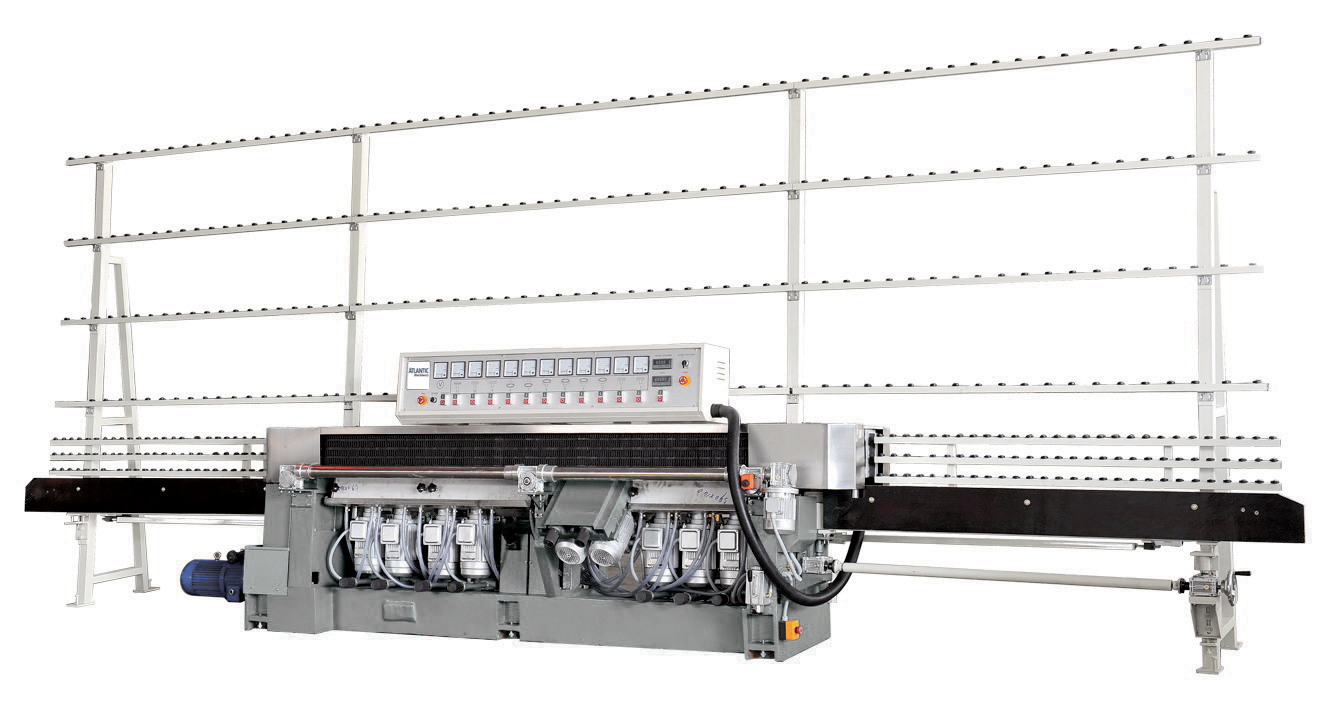

10 Spindle SLE

The ASL10.325A is a 10-spindle edger for grinding and polishing bottom edges, with ground and polished arrises at the front and rear. It guarantees consistent brilliant finishes on glass from 3mm to 25mm thick, with a touchscreen PLC control unit automating polishing heads, eliminating periodic adjustments.

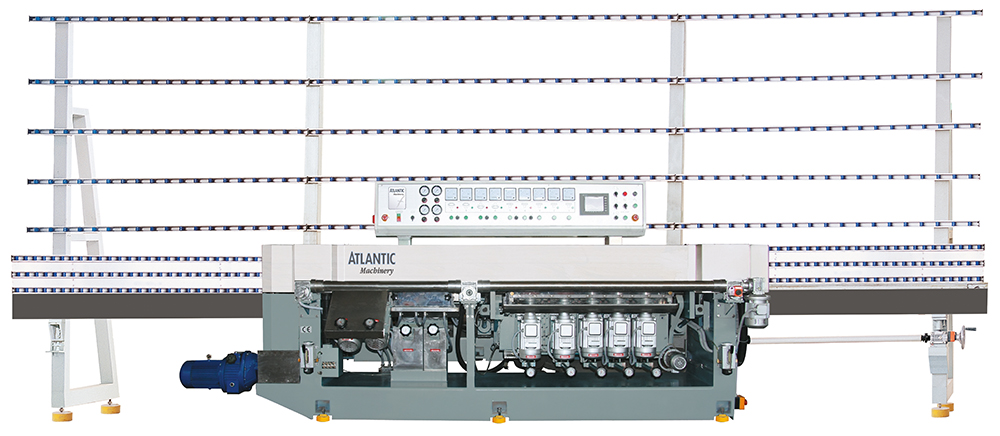

Straight Line Beveller

Our Straight Line Beveller is used for the production of bevelled mirrors and glass. The machine is

designed and manufactured to the exacting standards and accuracy that is required to produce

quality sharp accurate bevels. A chassis of stabilised cast iron, repeatedly tempered and machined lies as the heart of this precision equipment.