Call: 01455 251151

- Products

- New Equipment

- Used and Reconditioned Equipment

- Spares Parts

- After Sales Support

- Case Studies

- About Us

- Request Quote

SULAK Processing Equipment

Atlantic Machinery proudly offers SULAK’s high-quality glass processing machines, trusted in over 50 countries. From vertical drilling to edging and bevelling, SULAK machines deliver reliable, efficient performance, balancing quality and affordability for glass professionals of all sizes. Enhance your production with SULAK’s industry-leading technology.

-

Drills

-

Horizontal Edgers

-

Cutters

-

Belt Edging Machines

-

Crushers

VTS 05

Panther

The first vertical coordinates glass drilling machine features a revolutionary design that eliminates the need to relocate glass between drilling points, boosting productivity and saving 40% of working space. Controlled by a PLC system, it ensures precise X/Y axis positioning, with motion-controlled drilling heads, automated tool correction, and programmable coordinates. Additional features include a red laser, drill storage box, spindle lighting, and pneumatic fixture control, all included in the price.

VTS 04

L-Boxer Maxi

This glass drilling machine efficiently handles hole sizes from 5 to 100 mm, featuring two drilling heads for clean, burr-free results. Its motorised vertical adjustment with dual speeds ensures easy glass handling, while a robust frame and low power consumption (1.8 kW) enhance efficiency. The compact design saves floor space, and ergonomic one-handed operation simplifies use. Precise coordinate control and a well-developed backstop system boost productivity. Included are a red laser, additional lower base, and drill storage box. With low operating costs and a 2-year warranty, this machine is a reliable and affordable workshop solution.

VTS 04

A-Boxer

The VTS 04 A-BOXER is an advanced automatic double-sided drilling machine, enabling simultaneous drilling from both sides for fast, precise, and burr-free results. Featuring IAI drill head drives, adjustable drilling pressure reduces the risk of glass breakage, and operation status is displayed via an LED signal tower. Advantages include intuitive touchscreen control, digital position measurement, tool correction, high operational load, and compact, space-saving design. Standard features include a red laser, additional lower stand, drill storage box, pneumatic fixture control, LED spindle lighting, and digital X/Y axis measurement, ensuring efficiency and ease of use.

VTS 04

L-Boxer

This glass drilling machine efficiently drills holes from 5 to 100 mm with a two-head system for clean, burr-free results. Its motorized vertical adjustment offers two speeds for easy handling, while a robust frame and low power consumption (1.8 kW) ensure reliability. Compact and ergonomic, it saves space and is easy to operate, with precise coordinate control and a backstop system to boost productivity. Included are a red laser, additional lower base, and drill storage box. Backed by a 2-year warranty, it’s an affordable, efficient solution for any workshop.

VTS 03

Scout

This glass drilling machine handles hole sizes from 5 to 100 mm with a two-head system for clean, burr-free results. A motorized vertical adjustment with two speeds ensures easy glass handling, transitioning to faster speeds within three seconds. With a robust frame, 900 mm drill depth, and low power consumption (1.8 kW), it’s both efficient and cost-effective. The compact design saves space, while precise coordinate control and ergonomic one-handed operation enhance usability. Backed by a 2-year warranty, this machine is a reliable and affordable workshop solution for increased productivity.

VTS 03

FP

This glass drilling machine is designed for efficient hole drilling from 5 to 100 mm, featuring a two-head system for clean, burr-free results. Its motorized vertical adjustment, with two speeds transitioning within three seconds, ensures easy handling. With a drill depth of 750 mm, low power consumption (1.8 kW), and compact, space-saving design, it combines affordability with productivity. Precise coordinate control and ergonomic one-handed operation make it user-friendly, while a 2-year warranty guarantees reliability. An ideal solution for cost-effective and efficient workshop performance.

VTS 02

F

This glass drilling machine efficiently handles holes from 5 to 100 mm with a two-head system for clean, burr-free results. Manual vertical feeding ensures smooth glass handling, while a well-developed backstop system boosts productivity. With low power consumption (1.8 kW), a compact, space-saving design, and precise coordinate control, it offers affordability and ease of use. Ergonomic one-handed operation and a 2-year warranty make it a reliable and efficient solution for any workshop.

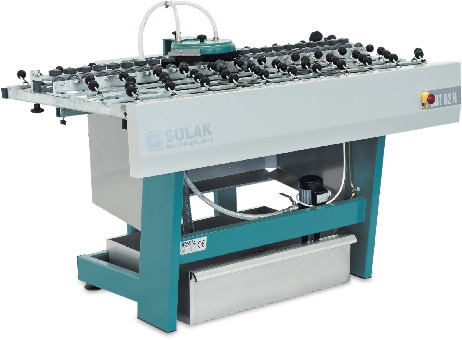

BBT 03

Uni

This edging machine is designed for edging and polishing flat or round edges of glass and mirrors, handling thicknesses from 3 to 12 mm. Using water-cooled diamond and polishing wheels, it processes "C," trapezoidal, or flat profiles with ease. With a zinc-dipped, robust frame and low power consumption (1.6 kW), it ensures durability and efficiency. Mobile and equipped with two wheels on one spindle, it’s simple to operate, requiring minimal experience. Backed by a 2-year warranty, this machine is a reliable and cost-effective solution for glass processing.

BBT 02

N

This edging machine is designed for polishing and edging flat or round edges of glass and mirrors, handling thicknesses from 3 to 12 mm. Using water-cooled diamond and polishing wheels, it produces "C," trapezoidal, or flat profiles efficiently. Easy to operate with minimal experience, it features low power consumption (1.6 kW), mobility, and a 2-year warranty, making it a reliable and user-friendly solution for glass processing.

RP 210

210

The polycarbonate cutter RP 210 is designed for cutting Multiwall polycarbonate sheets up to 20 mm thick. Operated by one person, it ensures easy sheet handling with a short shifting edge distance from the floor. Sheets are guided straight from the racks, and a laser pointer indicates the cutting trace. The precisely guided blade delivers straight, burr-free cuts. Features include zinc-dipped construction, easy blade replacement, low power consumption (400W), and minimal operating costs. Backed by a 2-year warranty, it offers efficient and user-friendly operation.

RP 210 F

210 F

The RP 210 F polycarbonate cutter is designed for cutting polycarbonate sheets up to 25 mm thick, operated easily by one person. Its low loading edge ensures smooth handling of large formats, with plates fed directly from rack trays. The infeed frame rotates to the desired position for precise cutting, guided by a laser pointer. The precision-guided knife delivers straight, clean cuts. Features include adjustable cutting speed, hot-dip galvanised frame, easy blade replacement, low power input (400W), minimal operating costs, and a 2-year warranty, making it efficient and user-friendly.

DTS

45

This glass crusher simplifies disposal, saving space while effectively crushing glass, including wire-glass. With a crushing capacity of 400 kg/hour, it handles glass thicknesses from 3 to 20 mm and sheet widths up to 420 mm. The output grain size ranges from 0.1 to 20 mm. Features include a noise-reducing double wall, outlet for industrial vacuum connection, and compact dimensions (650 x 850 x 1440 mm). It operates on 3 kW power, 3×400 V, 50/60 Hz, and weighs 90 kg, offering efficient and space-saving glass disposal.

As machine manufactures we are happy to adapt our machines and make bespoke alterations to our machinery range to meet customers requirements.

Atlantic Machinery Limited stands as a premier international manufacturer and supplier, renowned for delivering top-tier machinery tailored for the Insulated Glass and Glass Processing Industries.

Our diverse range of Insulated Glass Equipment spans from compact hot melt machines to cutting-edge automatic IG assembly lines. Notably, our Atlantic Glass Washers boast widths ranging from 1.3 meters to 3.0 meters, accommodating glass thicknesses from 2 to 50 millimeters, and featuring brush combinations of 2, 4, 6, and 8 brushes for optimal cleaning performance. Additionally, our processing machinery encompasses a wide array of equipment, including drilling, edging, arising, bevelling, sandblasting, and laminate cutting solutions.

Popular Ranges

© 2026 Atlantic Machinery. All Rights Reserved. Privacy Policy | Terms & Conditions | Site Map | Designed by: CBD