Call: 01455 251151

Roller Press

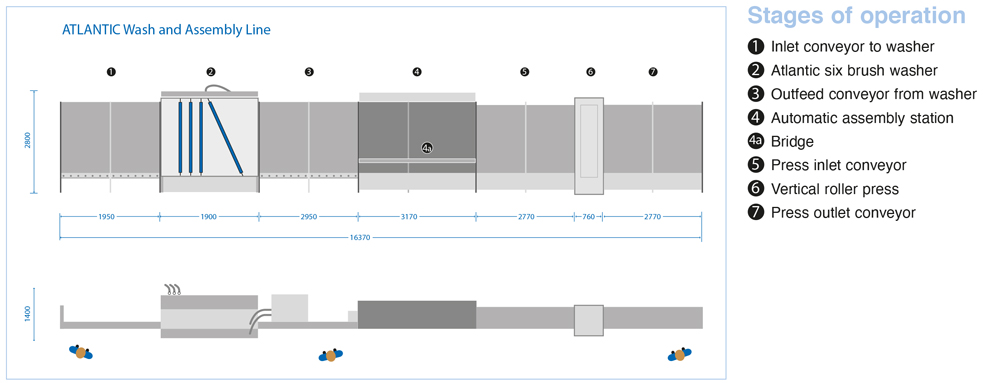

This PLC-controlled machine efficiently presses pre-assembled units with Poly-Iso-Butylene (PIB) applied to the spacer bar, creating a primary sealed unit ready for gas filling and final sealing. It's versatile, accommodating structural foam spacer bars like 'Superspacer'. The press seamlessly integrates into a semi-automatic line or operates as a standalone unit at the end of an existing glass washer unit.

Features

- Vertical press with parallel rubber rollers.

- Racks are fully conveyor driven with bevel gear drive.

- Sensors detect the height of the glass and the roller pressure is adjusted via the plc controller.

- Speed 20-45sec per sealed unit.

- Vertical edges are pressed for a longer duration to help achieve an even seal.

- Available press heights 1.6mtr, 2mtr, 2.5mtr.

- Rack size available 2000mm, 2800mm, 3600mm.

Ancillaries

- Alignment racks for spacer bar positioning

- Tilting table to drop large units to the horizontal for sealing

Services

- Electric 3 phase rated at 16Amps per phase plus neutral

- Compressed Air 3 c.f.m. 100psi.