Call: 01455 251151

Insulated Glass Assembly Lines

Insulated Glass Assembly Lines: Crafted in our UK factory, these streamline the production of double and triple glazed units, ensuring quality from CAD drawing to installation, backed by reliable after-sales support.

Insulated Glass Assembly Lines Defined

Insulated Glass Assembly Lines are specialised production lines designed for the manufacturing of insulated glass units (IGUs), also known as double and triple glazed units. These lines typically consist of various stations and machinery where the components of insulated glass panels, such as glass panes, spacers, and sealing materials, are assembled together.

Insulated Glass Assembly Lines are essential for efficiently producing high-quality insulated glass units used in windows, doors, and other architectural applications where thermal insulation and soundproofing are important considerations. These lines are often automated to streamline the production process and minimise human error, resulting in consistent and reliable output.

A selection of Insulated Glass Assembly Lines Videos

Automatic Assembly Lines

The Atlantic computerised assembly line optimises insulated glass unit production, seamlessly handling double and triple glazed units in automatic mode, with options for semi-automatic and wash-only modes for shaping and non-assembly tasks.

Roller Press

This PLC-controlled machine presses pre-assembled units with PIB applied to the spacer bar, creating a sealed unit ready for gas filling. It accommodates structural foam spacer bars and can integrate into a semi-automatic line or function as a standalone unit after a glass washer.

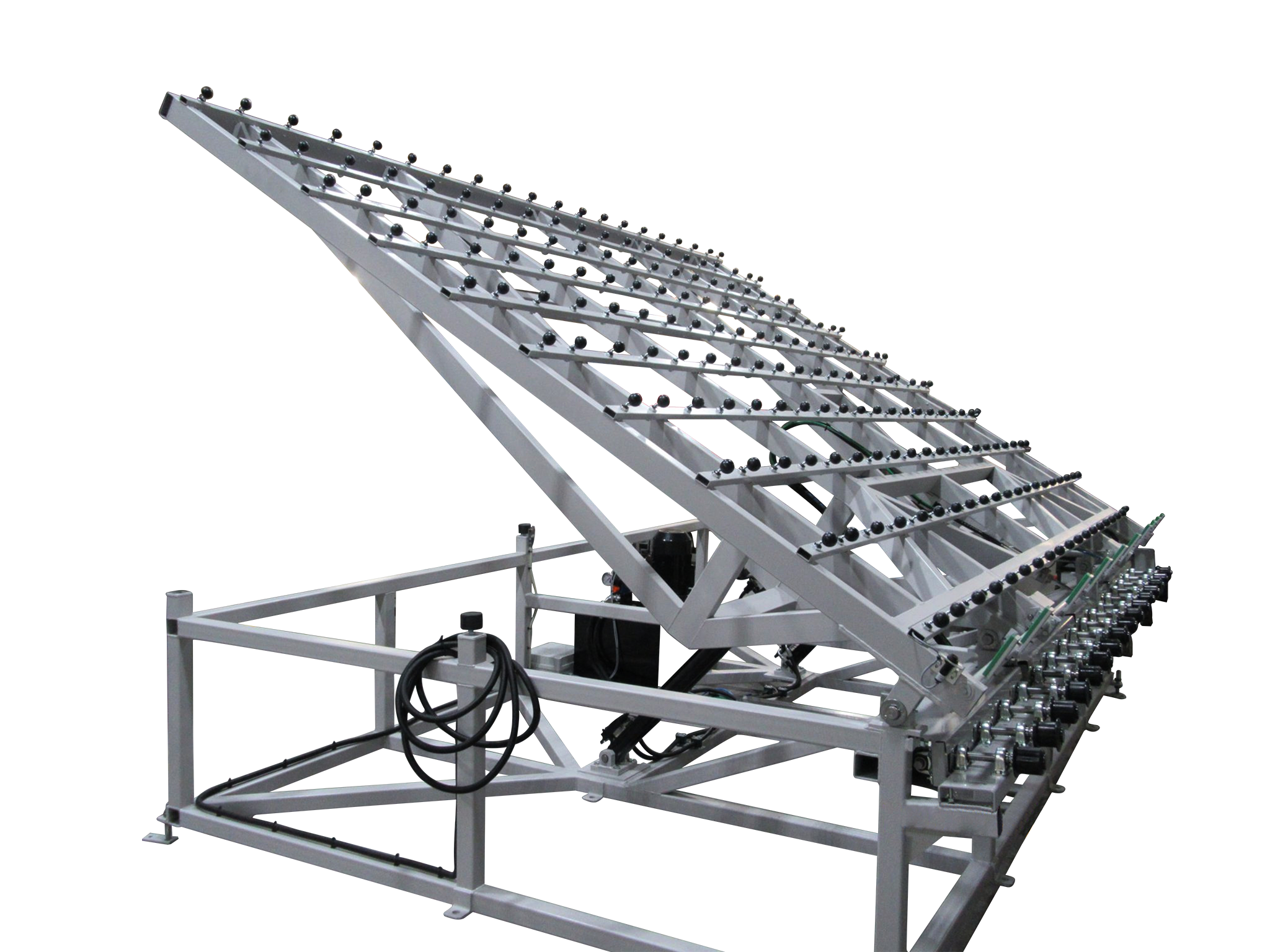

Hydraulic Tilting Table

Overview: The Hydraulic Tilting Table enhances glass processing by smoothly tilting glass panes for easy loading and unloading. Its hydraulic mechanism ensures efficiency and ergonomic benefits, making it a valuable addition to any glass workshop.